-

Phone

86-532-55676229

-

Address

No. 783, Huadong Road, Gaoxin District, Qingdao, Shandong, China

-

E-mail

LatestProducts

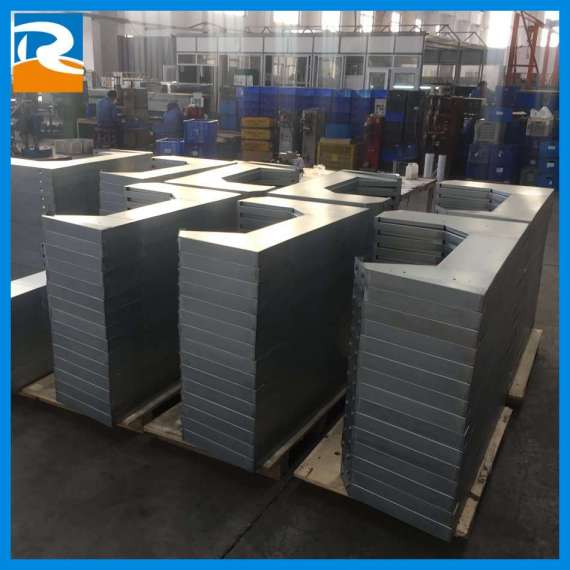

Customized Precision Metal Parts/Sheet Metall Fabrication/Auto Parts/Hardware Spare Parts for Testing Equipment /Automation Equipment/Communication Equipment

China Customized Precision Metal Parts/Sheet Metall Fabrication/Auto Parts/Hardware Spare Parts for Testing Equipment /Automation Equipment/Communication Equipment, Find details about China Aluminium Cabinet, Euipment Case from Customized Precision Metal Parts/Sheet Metall Fabrication/Auto Parts/Hardware Spare Parts for Testing Equipment /Automation Equipment/Communication Equipment - Qingdao RXT Yixiang Technology Co., Ltd.

Description

Basic Info

- Certification: ISO9001, Ts16949

- Size: Customized

- Transport Package: PP Bag + Plastic Foam + Carton Packaging

- Origin: Qingdao, China

- Item: Electric Tank Shell

- Trademark: RXT

- Specification: Customized

Product Description

1.Stamping tensile series description :

Stamping tensile are abundant in variety, mainly including auto parts, printer accessories, borne power amplifier shell, switches, ballast shell, and set-top box enclosure. Tensile products include all kinds of water dispenser tank, stainless steel tank and all kinds of lamp holder lamp ring, etc..

We constantly provide all kinds of auto production accessories for large domestic automobile manufacturers, which have passed the strict quality audit of these manufacturers.

2.Product show:

3.Product details:

4.Our advantages:

1)Quick response within 24 hours.

2)Manufacturer with 6 years experiences.

3) High quality and competitive price.

4)OEM/ODM:custom fabrication according to your drawings or samples.

5)Small order is acceptable.

6)Certification:ISO9001:2008,TUV,SGS.

5.Sample

Step1: provide your drawing and requirements to us.

Step2: we make quotation.

Step3: negotiation and confirm product details.

Step4: confirm sample cost, freight and delivery.

Note:

Sample unit cost will be 3 times based on the final quotation.

Because samples are customized, it takes us more labor costs than mass production.

Usually sample delivery time is around 10 to 20days.(up to the products)

Step5: provide PI to you, you make payment accordingly.

Step6: we start production, and keep you informed updated news.

Step7: send you details and photos when qualified sample is finished.

Step8: make shipment after above information is confirmed.

6.Delivery&Shipping:

Delivery time: 20 to 40 days (up to products and order qty.)

Shipment: According to your needs, we can arrange shipment by sea, air and courier to your ports. Also we can deliver goods to other cities of China.

PRICE TERM AND PAYMENTMETHOD:

EXW, FOB, CNF, CIF

T/T, L/C at sight

Note: 30% deposit is required before production, because we do customized products for clients, we unable to sell them to others, have to reduce our risk. Hope you can understand.

AFTER SERVICE:

Provide technical support during your assembling, installing and reprocessing.

Refund and rework policy for quality problem.

Stamping tensile are abundant in variety, mainly including auto parts, printer accessories, borne power amplifier shell, switches, ballast shell, and set-top box enclosure. Tensile products include all kinds of water dispenser tank, stainless steel tank and all kinds of lamp holder lamp ring, etc..

We constantly provide all kinds of auto production accessories for large domestic automobile manufacturers, which have passed the strict quality audit of these manufacturers.

2.Product show:

3.Product details:

| Materials: | SPCC, SGCC, SECC, SPHC, Stainless steel, carbon steel,copper,aluminium, brass, iron, and bronze etc. |

| Processing Craft: | Laser Cutting, CNC Punching, CNC Bending, Riveting, Grinding, Stamping, threading,welding, polishing,tapping,riveting,assembly. |

| Surface Finished: |

Galvanized(zinc-plated, nickel-plated,chrome-plated,silver-plated), powder coating, polishing(mirror polishing, electrolytic polishing), brushing,sand blasting,chemical etching,passivation treatment, etc. Hot Galvanized, Painting,Cataphoresis, Chrome/Zinc/Nickel Plating/Anodize/ Silk-screen etc; |

| Tolerance | +/-0.01mm |

| Major Equipment: | TRUMPF Laser cutting machine |

| CNC shearing machines | |

| CNC punching machines | |

| CNC bending machines | |

| TIG welding machines | |

| MIG welding machines | |

| SPOT welding machines | |

| STAMPING MACHINE; | |

| Stamping machines | |

| Pipe bender | |

| U-shape extrusion press | |

| Cold press | |

| Turning machine | |

| Milling machine | |

| Grinding machine | |

| Oil hydrulic press | |

| Serve Type: | OEM,ODM; |

| Files Formats: | Pro/Engineer, Solidworks, Auto CAD,PDF |

| Certification: | ISO9001:2008,TUV,SGS |

| Package | Plastic film+harden carton box+plywood case or plastic film+band+tray |

| Application | Auto parts,Food Machinery,medical testing and equipment, electronic products, electric appliance,power switches, miniature switches,A/V equipment. |

| Features |

1.Customized Design 2.Small Order Allowed 3.Sample Product Available 4.Competitive Price due to factory direct supply |

1)Quick response within 24 hours.

2)Manufacturer with 6 years experiences.

3) High quality and competitive price.

4)OEM/ODM:custom fabrication according to your drawings or samples.

5)Small order is acceptable.

6)Certification:ISO9001:2008,TUV,SGS.

5.Sample

Step1: provide your drawing and requirements to us.

Step2: we make quotation.

Step3: negotiation and confirm product details.

Step4: confirm sample cost, freight and delivery.

Note:

Sample unit cost will be 3 times based on the final quotation.

Because samples are customized, it takes us more labor costs than mass production.

Usually sample delivery time is around 10 to 20days.(up to the products)

Step5: provide PI to you, you make payment accordingly.

Step6: we start production, and keep you informed updated news.

Step7: send you details and photos when qualified sample is finished.

Step8: make shipment after above information is confirmed.

6.Delivery&Shipping:

Delivery time: 20 to 40 days (up to products and order qty.)

Shipment: According to your needs, we can arrange shipment by sea, air and courier to your ports. Also we can deliver goods to other cities of China.

PRICE TERM AND PAYMENTMETHOD:

EXW, FOB, CNF, CIF

T/T, L/C at sight

Note: 30% deposit is required before production, because we do customized products for clients, we unable to sell them to others, have to reduce our risk. Hope you can understand.

AFTER SERVICE:

Provide technical support during your assembling, installing and reprocessing.

Refund and rework policy for quality problem.